Energy is an important material foundation for human survival and development, driving the sustained development of the global economy and the continuous improvement of human quality of life. Textiles, which may seem unrelated to the energy field, play an increasingly important role in the innovation of energy technology.

Textiles, with their unique physical and chemical properties, have shown broad application prospects in traditional energy fields such as thermal power and petroleum, as well as new energy fields such as wind power, hydrogen energy, photovoltaics, and batteries. These applications not only improve energy conversion efficiency, but also promote the sustainable development of energy technology. With the continuous expansion of the application of textiles in the energy field, new fiber materials and innovative textile processes continue to emerge. The performance and functionality of energy textiles continue to improve, playing an irreplaceable role in safe production, efficient operation, stable transmission and other scenarios in the energy industry.

At the CINTE24 exhibition, a large number of energy textiles were also showcased in the advanced technology textile exhibition area, aiming to promote communication and cooperation between the upstream and downstream of the industrial chain, accelerate the transformation of industrial textile technology achievements, new products, new technologies, and high-end applications, and help build a diversified and clean energy supply system.

Textiles have a wide and important application in coal, oil, and natural gas mining, electricity production, and transmission, playing a positive role in technological innovation, efficient operation, safety production, energy conservation, and emission reduction in the energy industry. In the field of thermal power, the large-scale application of bag filter technology in thermal power plants has significantly reduced dust emissions; The requirement of “ultra clean emissions” promotes the advancement of filter material technology, with a large number of applications of ultra-fine surface layer gradient filter materials, membrane filter materials, etc., and continuous improvement of different sealing technologies; In addition, the application of high-strength polyester fiber flexible mesh in coal mine support has improved the retreat efficiency and safety guarantee level of the fully mechanized mining face; The application of gas film materials in the construction of power plant coal sheds effectively blocks the diffusion of coal dust; Textile reinforced conveyor belts are important tools for coal transportation in power plants

In the field of power transmission, high-strength overhead conductors enhance the load-bearing capacity of transmission lines, while cable wrapping materials and insulation paper ensure the safety and stability of power transmission; The shielding suit effectively protects the safety of the workers.

In the petroleum industry, fiber-reinforced hoses provide safety protection for oil transportation; Corrosion resistant and damage resistant sucker rod protective covers and pipeline repair materials extend the service life of equipment; Special fabrics used for filtration and separation to improve oil recovery efficiency; Explosion proof and anti-static textiles ensure the safety of petroleum production.

The development of the new energy industry has expanded the breadth and depth of the application of textile materials in the energy field. With the increasing trend of large-scale and lightweight wind turbines, as well as the rapid development of offshore wind power, the application scope and scale of carbon fiber in wind turbine blades are gradually increasing. For economic reasons, the current mainstream blades are made of fiberglass. However, under the condition of meeting the requirements of stiffness and strength, carbon fiber fan blades will reduce their weight by more than 30% compared to mainstream fiberglass blades, which can significantly reduce the weight of blades and meet the demand for lightweight large blades. According to GWEC (Global Wind Energy Council) data, when the length of wind turbine blades exceeds 40m, the cost of comprehensive materials, labor, transportation, and installation decreases. Therefore, using carbon fiber to make blades is more economical than using glass fiber.

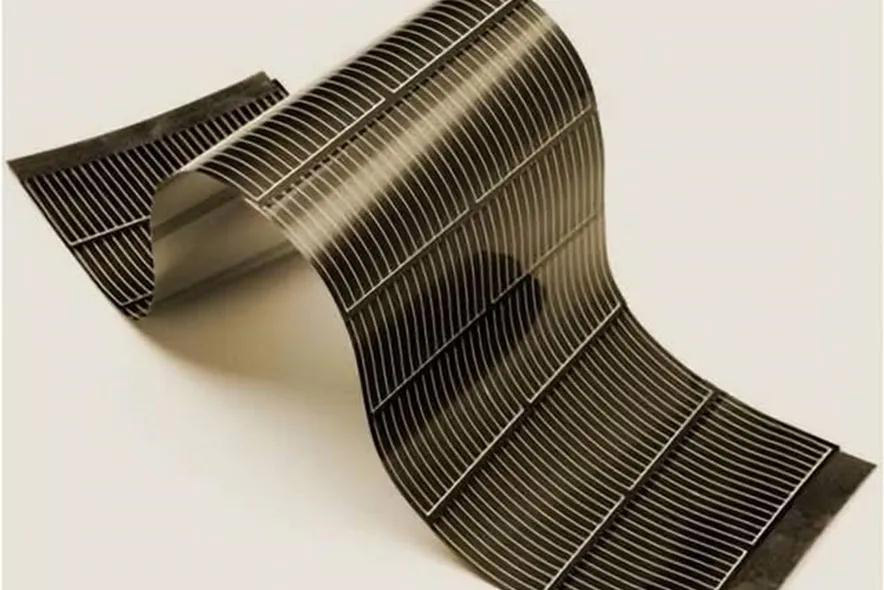

In addition, carbon fiber composite materials, fiber membrane materials, and wire mesh materials are not only widely used in the production processes of photovoltaics, lithium batteries, and hydrogen energy, but also important components of these new energy products. In the field of photovoltaics, textile composite materials continue to provide advanced solutions for the upgrading of the photovoltaic industry, while carbon composite thermal field components help improve the efficiency and safety of crystalline silicon production; Flexible and efficient packaging fabric enhances the stability and durability of photovoltaic cell groups; Fiber materials such as printing screens are used to manufacture photovoltaic modules, reducing raw material costs and improving light energy conversion efficiency.

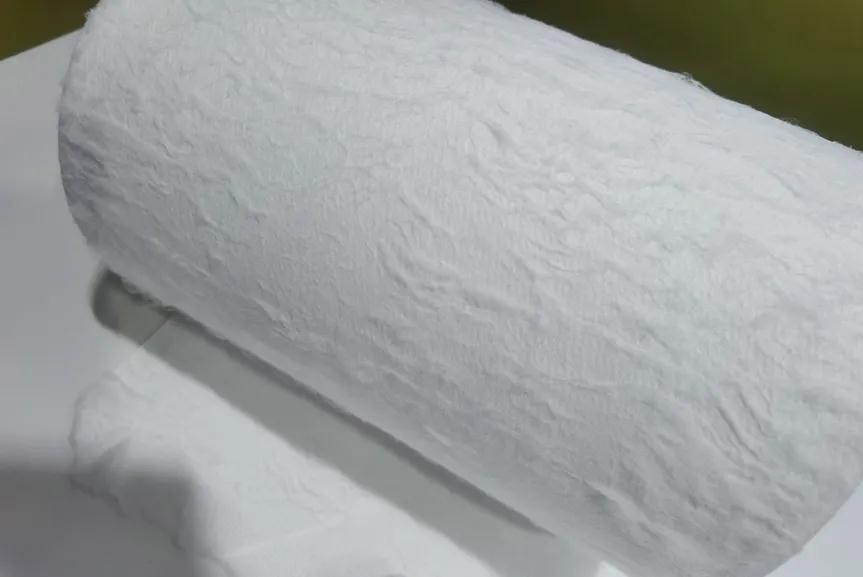

In the field of batteries, fiber based separator materials can effectively prevent short circuits between positive and negative electrodes, improve the charging and discharging performance and safety of batteries; Fiber electrode materials improve the conductivity and structural stability of electrodes; The high-temperature resistant and flame-retardant outer packaging fabric enhances the safety of battery use.

In the field of hydrogen energy, high-performance battery separators can be used for electrolytic hydrogen production, high-performance fiber composite materials are used to manufacture hydrogen storage containers, and fabrics with good airtightness and corrosion resistance are used for the protection of hydrogen transmission pipelines.

Multi layer non-woven fabric edge splicing, unfolded non-woven fabric width can reach tens of meters, ultra wide non-woven fabric joining machine!

Post time: Jan-03-2025