Knowledge related to non-woven fabric composites

The first thing we need to know about Liansheng non-woven fabric is composite. The term ‘composite Liansheng non-woven fabric’ is a compound word that can be divided into composite and Liansheng non-woven fabrics.

Composite refers to the bonding of two or more materials together through chemical or physical methods (such as glue or high temperature). Shandong non-woven fabric is a species name with many varieties. It is the diversity of Liansheng non-woven fabrics that forms the foundation of composition. So composite Liansheng non-woven fabric is a composite of different types of Shandong non-woven fabrics or a composite of Shandong non-woven fabrics and other materials.

By combining various materials in terms of performance, we can complement each other’s strengths and weaknesses, making the comprehensive performance of composite Liansheng non-woven fabric superior to the raw materials and meeting various requirements.

Next, let me introduce the method. This is the key point of the entire article. The following is the existing or upcoming composite Liansheng non-woven fabric:

1、 Composite between non-woven fabrics

(1) Spunbonded spunlaced non-woven fabric (the spunbonded spunlaced non-woven fabric referred to here is not commonly referred to in the industry as spunbonded spunlaced non-woven fabric, nor does it include spunbonded microfiber spunlaced fabric, which is a composite between two types of sheets). Spunbonded non-woven fabric and spunlaced non-woven fabric are hot-rolled and pressed, added with adhesives (chemical, physical, etc.), and processed with composite (such as needle punched, etc.). This type of non-woven fabric is currently applied in the field of wiping cloth;

(2) Spunbonded needle punched non-woven fabric, like the aforementioned spunbonded water spunlaced Shandong non-woven fabric, is not commonly referred to as spunbonded needle punched non-woven fabric in the industry, nor does it include spunbonded super fiber needle punched fabric. It is a composite between two types of sheets. Spunbonded non-woven fabric and needle punched non-woven fabric are hot-rolled and pressed, added with adhesives (chemical type, physical type, etc.), and processed composite (such as needle punched);

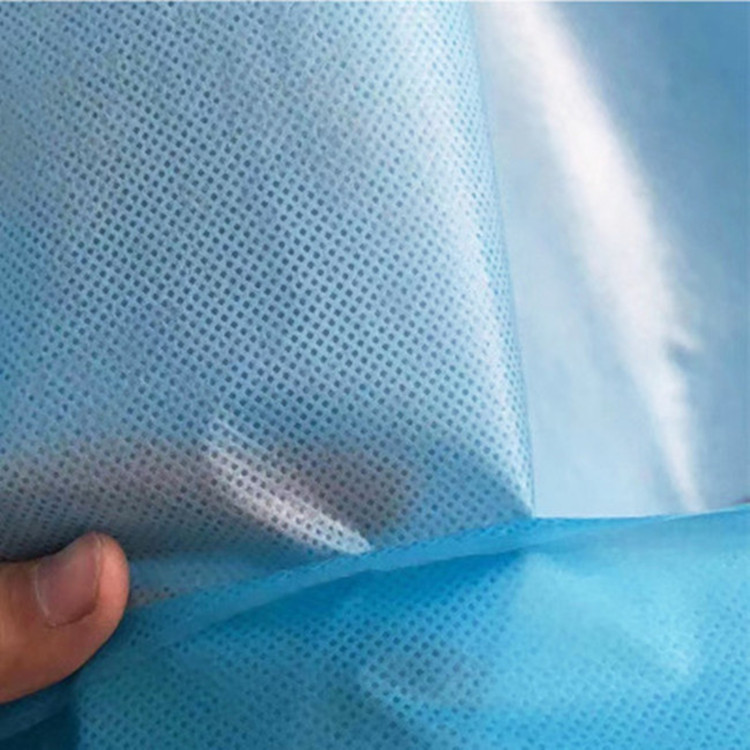

(3) Spunbonded melt blown non-woven fabric refers specifically to the offline composite of spunbonded fabric and melt blown fabric. Spunbonded Shandong non-woven fabric and melt blown non-woven fabric are processed through hot rolling, adding adhesives (chemical, physical, etc.), and process composite (such as needle punching, etc.);

(4) Melt blown spunlace non-woven fabric, a composite of two types of sheets, or sandwich (four Meiji, five Meiji, etc., as long as you like) laminated non-woven fabric, the lamination method can be hot rolled, added with adhesives (chemical type, physical type, etc.), process composite (such as acupuncture, spunlace, etc.), and other composite methods you can think of;

(5) Melt blown needle punched non-woven fabric, composite of two types of sheets, or sandwich (four Meiji, five Meiji, etc., as long as you like) laminated Shandong non-woven fabric, the lamination method can be hot rolled, added with adhesives (chemical type, physical type, etc.), process composite (such as needle puncture, water puncture, etc.), and other composite methods you can think of;

(6) Spunbonded sewn composite non-woven fabric, a composite of two types of sheets, or sandwich (four Meiji, five Meiji, etc., as long as you like) laminated non-woven fabric, the lamination method can be hot rolled, added with adhesives (chemical type, physical type, etc.), process composite (such as needle pricking, water pricking, etc.), and other composite methods you can think of;

(7) Spunbonded wet non-woven fabric is a composite of two types of sheets, laminated Shandong non-woven fabric. The lamination method can be achieved through hot rolling, adding adhesives (chemical, physical, etc.), and process lamination (such as needle punching, water pricking, etc.). Therefore, when making products, customers need to select materials, and the lamination order of each material is arranged according to the product performance requirements.

2、 Composite between non-woven fabrics and common materials

Due to the different compatibility between different materials, compatibility is a crucial issue in achieving good composite effects. If there is good compatibility between materials, the composite effect will be very good. Another issue to consider is temperature. Many materials have good composite effects at high temperatures or in a molten state, but once the temperature drops, Unexpected effects may occur, such as bubble formation, easy peeling, fragility, etc.

(1) Non woven fabrics and paper (paper pulp or paper) composites are currently available in the market, including wood pulp spunlace non-woven fabrics, spunbond and paper composites, hot air non-woven fabrics and paper composites, and chemical bonded non-woven fabrics and paper composites. We may also use paper from the paper industry, which can be combined with non-woven fabrics, and select materials according to the application situation;

(2) Composite of non-woven fabric and plastic film (mainly referring to the composite of materials that are already thin films with non-woven fabric, and the materials for coating and coating are specified separately), composite of non-woven fabric with PE, PP, PET, PTFE, PVC, PC, and other materials that can be made into plastic film. Most of these materials use non-woven fabric as a carrier to jointly complete the properties of a material;

(3) Non woven fabric and metal foil composite, the main metal foils are aluminum, copper, iron, and gold. If other metal foils are used for composite, they can also be used;

(4) Composite of non-woven fabric and mesh material, where the mesh material includes textile woven mesh, plastic mesh, metal mesh, and other organic and inorganic mesh;

(5) Non woven fabric and fabric composite, where the fabric can be knitted, woven, and all other sheet like fabrics;

(6) Composite of non-woven fabric and sponge material, all polymer materials that can be made into sponges can be composite with non-woven fabric, and various sponges, polyurethane, PVA, etc. can be selected as needed; Note: For non-woven fabric double-layer composite materials, let’s write it here temporarily. The composite of the above sheets can be achieved through adhesive lamination, physical lamination, and other new process lamination methods, so that the two materials can be combined together to bear different aspects of their product performance.

3、 The composite of non-woven fabrics with other powder, resin, metal, and fiber materials may not be accurate here, but a more accurate statement would be fusion.

(1) Non woven fabrics adhere powder, resin, metal, or other materials to the surface of non-woven fabrics or the interior of Shandong non-woven fabrics through coating process, forming a stable whole;

(2) Non woven fabrics adhere powder, resin, metal, or other materials to the surface of non-woven fabrics or the interior of Shandong non-woven fabrics through impregnation process, forming a stable whole;

(3) Non woven fabrics are sprayed (sprayed) onto Shandong non-woven fabrics by applying polymer resins or materials through hot melting or chemical processes, forming a balanced and stable overall structure;

(4) Coating non-woven fabrics can be achieved by using chemical coating and electrochemical coating methods to form a layer of film on the surface of the non-woven fabric, achieving surface treatment of the non-woven fabric;

(5) Non woven fabrics and resin (polymer) materials are compounded by applying resin (polymer material) to the surface of the non-woven fabric through rolling to achieve the combination of two or more materials;

(6) The composite of non-woven fabrics and fiber materials can be applied to the surface of non-woven fabrics through chemical bonding and thermal bonding, achieving the corresponding effect on the surface of non-woven fabrics

Post time: Nov-11-2023